-40%

Blast Cabinet Metering Valve: Low Cost Harbor Freight Sandblaster Upgrade Valve!

$ 24.81

- Description

- Size Guide

Description

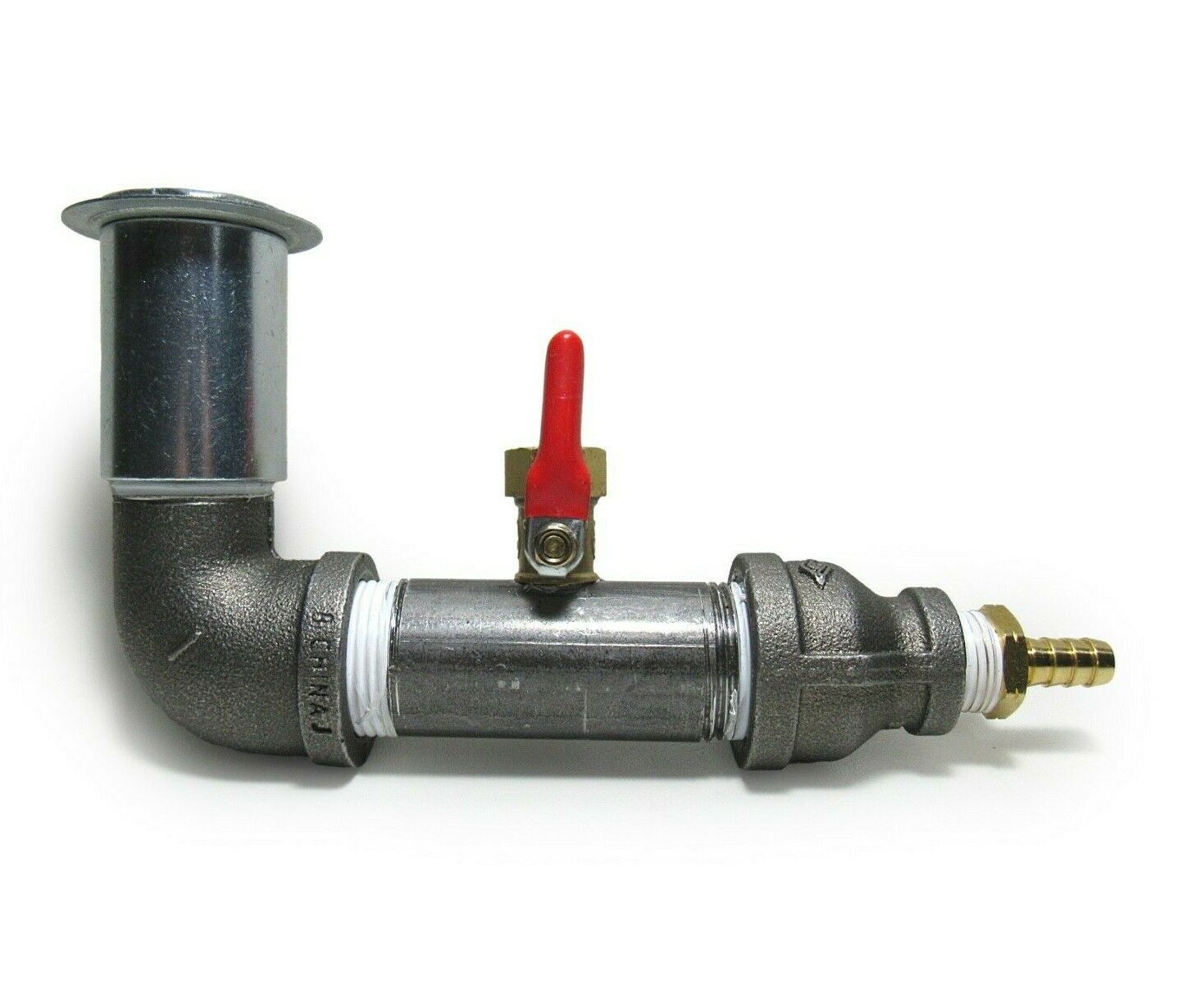

This abrasive blast cabinet metering valve combines great performance and a great price! Eliminating the drain plug from the design reduces costs and improves media flow. There’s no messy drain plug to struggle with or lose and less area for internal restrictions. You can still empty media by lowering the door as you've always done. The smoother design naturally funnels media into the valve. I even take the time to mill a bevel on the internal edge of the connections near the hose to further improve flow. Features: Durable metal construction. Permanent rust preventative coating. Sealed connections. Easy install. Full size 3/8” air inlet valve offers easy toolless adjustment. Purchase includes metering valve and instructions only. Click or tap “See full description” below for more infoAffordable Low Cost DIY Harbor Freight Blast Cabinet Metering Valve

The Most Economical Sandblaster Metering Valve Solution!

Huge improvement over the horrible stock siphon tube design: Better, faster blasting with less media. (Even with the stock gun!)

Affordable

Durable: Constructed with heavy duty metal components

More Free Flowing Design: Media Flows more freely and rapidly

Tool Free Adjustment: Adjust inlet airflow in seconds with just a finger or two. No tools required!

Clear rust preventative coating applied

Sealed threaded connections

Easy to install with clear instructions provided

Installs on Harbor Freight and similar economical blast cabinets featuring a hinged media dump door at the bottom of the hopper etc.

Designed for improved flow: No drain plug = smoother, faster media flow and cost savings.

Custom machined beveled internal edges at the hose connection improve flow.

Perfect solution for those who are willing to sacrifice the media drain plug for increased flow, performance and associated cost savings.

Ideal for those who don't change media often

Full size 3/8" air inlet valve for better air flow

Ready for use with 1/2" hose but that can be changed if need be.

Your purchase includes a blast cabinet metering valve similar to the one pictured and printed installation instructions.

Need a kit with blast siphon hose included? Want a valve with a drain plug? Check out my other listings!

https://www.ebay.com/sch/dcmimpala/m.html

I've put together what I consider to be a great economical DIY abrasive blast cabinet metering valve. In my opinion it offers the perfect combination of affordability, durability and effectiveness.

I use this exact metering valve setup on my Harbor Freight 40 lb/60 gal capacity blast cabinet (#68893) almost daily. I have used the similar drain plug design and the much more expensive professional cast aluminum ones. I prefer this particular design above the others.

Additional Details:

Use with multiple media types.

Measures approximately 4.5" tall x 8'' l

ong x 1.75" wide

Ready for 1/2" blast media tubing. If you need it set up for a different hose size please inquire before purchasing. I may be able to accommodate your needs and I can let you know the price difference if any.

No Drain Plug and Beveled Edges for Improved Flow:

I'll let you in on a little secret. You don't

need

a drain plug in your blast ca

binet metering valve. The f

ittings to make that happen add to the overall cost and weight of your metering valve. More importantly, they

also create additional areas for blast media to get hung up and where its flow will be slightly impeded.

On paper a drain plug in the bottom of your Harbor Freight sandblast cabinet metering valve sounds great. When you actually use one and start to think about things critically, in most cases the drain plug really isn't necessary . . . or even all that more convenient.

This design eliminates the drain plug design and works even better by naturally funneling the abrasive media into the mixing area.

I even take a few minutes extra to mill/machine a beveled edge inside the valve at the hose connection to eliminate square edges and provide smoother media flow. In my experience, the

result of all this is improved flow that

equates to better blasting performance.

Draining the Media With No Drain Plug:

This sandblaster metering valve is for those of you who have the blast cabinet with the flip down media trap door on the bottom of the hopper. That door still functions just fine with this valve installed. All you do is drill a hole in the existing door to install this abrasive mixing valve. If you leave enough slack in the media hose you can simply unlatch the door and empty the cabinet just like you've always done. In the worst case scenario, you may have to disconnect the media hose to allow enough room for the door to swing down to empty sand.

This valve should clear the inside of a 5 gallon bucket. I use this exact metering valve on my Harbor Freight blast cabinet and I empty it into a 5 gallon bucket. If you have clearance issues under your blast cabinet because you installed a bottom shelf etc, you can always cut down or modify a bucket or find a wider lower profile container etc. Even a cardboard box will work in a pinch. You often only need a few pounds of media or less with this valve modification installed, so media swaps and cleaning are easier than ever to begin with!

The good news is you can still use the blast media dump door on your hopper. The GREAT news is with this valve you won't be emptying media often.

With the awesome performance of this bottom gravity fed metering valve design you use much, much less media for blasting. You only need enough media to ensure the bottom of the hopper stays covered so the metering valve and blast hose stay filled with sand.

I personally don't miss the drain plug at all. When I'm emptying media I'm usually cleaning or doing maintenance on the cabinet anyways.

Affordable:

This design is essentially the most economical metering valve I can build with durable all metal parts. Eliminating the bulky drain plug design saves on assembly costs and shipping costs. Those are savings I pass on to you. I've priced this so it isn't even worth your time to run around attempting to build one on your own. In fact, if you don't have a couple of the specialized tools necessary you'd likely end up paying more than I'm charging.

Saving money is great, but when you save money

and

get better performance that makes the deal even sweeter! In my experience this blast cabinet metering valve flows a little better and performs better than the other designs.

Durable:

I build this blast cabinet metering valve with all major construction being done with metal components.

Sealed Connections:

All threaded connections outside the cabinet are sealed with thread sealant and/or pipe sealant tape to prevent leaks.

Sealing the threaded connections actually isn't necessary; I do it anyway for added security and piece of mind. This sandblaster metering valve operates on a suction or negative pressure principal and is typically under very low pressure. Air rushing through the gun pulls air into the air inlet valve and media through the metering valve. Basically air is trying to get into the pipe more than the sand or media is trying to get out.

Rust Preventative Coating:

I spray all steel components with a clear permanent rust preventative coating to prevent rust and corrosion. Most of the components typically have no coating from the factory and can rust and corrode without some protection. This is especially true in humid environments.

Installation:

Installation is simple. Detailed, easy to follow instructions printed instructions are provided with your purchase. You simply remove the drop down door on the bottom of your blast cabinet and drill a hole to mount the gravity fed blast cabinet metering valve. Hold the silver portion of the valve on the bottom of the door hole and use the included fitting to mount. Remount the door on the blast cabinet. Your 1/2" ID blast media hose slips on the brass fitting at the end of the metering valve. Since you're converting from the siphon tube that was previously mounted inside the cabinet, you'll need to route the media hose from the outside of the cabinet to the blast gun on the inside. This is typically done by drilling an appropriately sized hole in the side of your cabinet and installing a rubber grommet or bushing in the cabinet wall. This seals around the hose and protects it from chafing.

Please note, your purchase includes the sandblaster metering valve shown and printed instructions only. You need to supply your own blast cabinet media door, sand/media hose and grommet and any tools necessary for installation. Typical example of tools and equipment required: 1-1/4" diameter hole saw, drill, 1/2" ID blast media hose/tubing, grommet and necessary drill bits. You may need large channel locks, large pliers or a big adjustable wrench if you want to tighten the connection at the blast door snugly beyond hand tight.

ADVANTAGES OF THIS DESIGN OVER THE DRAIN PLUG DESIGN VALVE:

More affordable

Better media flow: Less restriction to media flow inside the tubing and fewer areas for media to collect and get hung up.

Lighter

Lower profile and less height. This design shaves about 2" off the length hanging off the bottom of the blast cabinet.

No drain plug to lose.

No reaching for a wrench to remove a drain plug. No cleaning dirty nasty blast media from drain threads to reinstall a drain plug.

DISADVANTAGES OF NOT HAVING A DRAIN PLUG:

Draining the blast cabinet sand or media may involve a few extra seconds if you have to remove the media hose to allow the door to swing down fully. (It usually isn't necessary. If it is, it doesn't typically take any longer than removing and reinstalling a drain plug does.)

Fishing a small part like a nut or bolt out of the metering valve may be slightly more difficult if it would somehow make its way inside the valve.

If you change media types frequently a drain plug may make things slightly easier. It may take you a few extra seconds to blow residual media out of the valve without a plug.

Upgrade Your Siphon Tube Blast Cabinet to a Metering Valve:

The Single Best Siphon Feed Abrasive Blast Cabinet Upgrade You Can Make!

Holy cow! If you have a Harbor Freight or other economy blast cabinet that uses the horrible siphon tube feed design, do this upgrade NOW. Seriously. Those posts you've seen all over the internet claiming this is the best mod you can do are correct. I don't care if you you buy this design, the design with the drain plug or someone else's product all together. You will be much happier with a gravity fed metering valve setup. I know from personal experience.

I struggled with perfecting the siphon tube design for years. I was worried switching to a metering valve would be a mistake. The thought of drilling a couple holes in my blast cabinet and setting it up only to be disappointed kept me from doing this mod for years. Instead, I messed around and made double tube custom siphon tube designs. That all helped a little and I'm confident I had the siphon tube design the best it could be. The problem is you can only improve a terrible design so much. Over the years I've wasted countless hours making sure the stupid pickup tube stayed clear and had sand over it. The stock design requires more blast media in the hopper and most of the time it isn't where you need it. Blast for a few minutes and then you'll need to address something: a clog, surging, the pickup tube is sucking air and isn't fully covered etc. You end up with a blast hopper full of 20, 30 or 40 lbs of wasted media and you still can't get good performance. What a nightmare!

A metering valve essentially eliminates all of these issues.

How Does it Work?

All of these metering valves essentially eliminate the terrible siphon pickup tube inside the blast cabinet. You drill a hole in the door or hatch at the bottom of your blast cabinet and mount the metering valve there. Your blast media falls into the metering valve via gravity. You hook a media suction hose up to the end of the metering valve and the other end to your blast gun. Gravity and the air flowing through the blast gun pull sand through the media hose. In addition, the air inlet valve allows for a rush of air flowing into the valve. That fresh air mixes with the media and improves flow and performance. This along with the shape and design of the metering valve and blast gun creates a sort of venturi effect that improves abrasive blasting performance dramatically over the stock siphon tube design.

Furthermore, adjusting the air inlet valve on the metering valve allows you to meter, or adjust, just how much sand blows through the gun. Allowing more or less air into the valve allows you to customize blast media flow. The result is much better performance and much longer blasting time compared to the siphon tube.

Once you're set up with correct air pressure combined with the right position of the air inlet valve, you can blast for hours without issues like surging or no media coming out! Once you've dialed things in correctly, you'll experience better blasting, faster and with less media: even with the stock gun!

FAQ: Frequently Asked Questions

1. Is installation difficult?

No. Easy to follow printed installation instructions are included. In the unlikely event you encounter any issues, just send me a message. I'll do my best to help!

2. What do I need to provide?

Only the metering valve and instructions are included with your purchase. You provide your existing blast cabinet media chute door, a 1-1/4" hole saw (or other means to cut a 1-1/4" diameter hole in it), your choice of 1/2" ID tubing for blast media, hose clamps, an appropriately sized grommet and drill bit, and some basic hand tools.

3. Does this only work on Harbor Freight sandblast cabinets?

No. I personally use this on the 40lb capacity, floor standing Harbor Freight blast cabinet (Item

#68893). It works great on that cabinet but this metering valve should work on any similar siphon tube style blast cabinet with a hinged bottom media hopper chute door. As long as you have a flat area at the bottom of your blaster hopper measuring 1-1/2" to 2" or more and enough room under your blaster to mount the valve you should be good to go. This blast cabinet metering valve can also work on many Eastwood, Jegs, Central Pneumatic, Princess Auto, Powerfist and countless economical Chinese blast cabinets. If in doubt send me some photos or a description of your cabinet and measurements of the hopper door bottom and I'll do my best to advise!

4. Will this work on a smaller bench top blast cabinet?

Not without modification to the cabinet and or the bench or table top. Most benchtop style blast cabinets don't have enough room below them if they are used sitting on a bench or table top. Accessing and adjusting the valve is difficult or impossible without cutting or drilling a hole in the benchtop for the valve to pass through. If your bench top blast cabinet is mounted to a cart or frame with room below you can usually make it work. I have made valves in the past that hang lower from the cabinet and allow for easier access to the valve. Contact me for details and pricing if you'd like me to create one for you. For a bench top style blaster without a hinged hopper door, I highly recommend upgrading to one of our metering valves with a drain plug to make emptying media much easier.

5. Do I need to upgrade to a foot pedal?

No. You can use this metering valve with or without a foot pedal setup.

6. Do I need to upgrade my blast gun?

No. This is still an amazing upgrade even if you're using the subpar quality stock gun that came with your cabinet. As long as your blast gun is in good condition and flowing air and media as intended, you don't need to upgrade. I'm still using the stock Harbor Freight blast gun because parts are dirt cheap and I can replace the entire gun for to if need be.

7. If a metering valve works so much better, why doesn't the manufacturer include one?

Cost. The main reason the economical Chinese blast cabinets don't include a metering valve is cost. It simply costs too much in materials and labor to make these additions in a hobby or entry level cabinet. Tossing in a cheap gun, tube and short section of hose is much cheaper and works "good enough" for blasting a few minutes here or there twice a year. Likewise, there's a reason the more expensive and better performing siphon blast cabinets do include a metering valve. They really DO work so much better.

8

. My blast media suction hose is bigger/smaller than 1/2". Can I still use this?

I'm happy to help customize this for your needs.

If you need a fitting for something other than 1/2" media feed hose feel free to contact me prior to purchase. I can probably make up a valve with the correct size fittings for your needs.

These are made with 1/2" ID hose fittings because that is the most common size. The size of blast media tubing you need depends on a variety of factors. The type and size of media you're using, blast nozzle orifice diameter, compressor size and output and more come into play. Few non industrial blasters or hobbyists with siphon cabinets are blasting with larger than 1/2" media hose.

Some people running with a smaller than ideal compressor compensate by using a smaller blast nozzle orifice and stepping down to 3/8" blast media hose. This helps slightly reduce air demand without significantly impacting blast performance. I'm happy to move you down from 1/2" hose fittings at your request. Please note pricing will be higher if I need to move you up to a fitting for larger hose.

8. How tight do I need to tighten the nut when I mount the valve?

Hand tight is typically good enough!

Getting the nut as tight as you can by hand is usually sufficient to seal and hold the valve in place. You can also use a large adjustable wrench or channel lock pliers to snug the fitting up if you desire.

Photos Are of Previously Purchased Items:

The listing photos shown are stock photos of previously sold items. Your purchase will look very similar, but minor differences are possible. At times I may use a slightly different valve for the inlet valve or fittings may look slightly different from those shown. The fit and function of the device will not be affected in any way.

Made by Hand - Scratches etc. are common and expected

These are made by hand using industrial parts. Some pieces may have minor scratches, tool marks from wrenches, clamps, tools etc. Some of the parts themselves arrive with minor surface imperfections before they are even put together. Some scratches and tool marks are to be expected. No worries. I won't ship you anything that looks terrible and I definitely won't send something damaged to the point where it impacts fit, function or performance!

FREE SHIPPING:

Free shipping is valid for US Customers only. Free economy shipping will be via the carrier and service of my choosing. Slightly faster shipping may be offered for an additional fee. Please review shipping options at checkout.

Returns:

I generally don't accept returns on items that have been used, modified etc. In the event I do accept a return I can offer exchange or your money back. Return shipping costs are typically the responsibility of the buyer, unless I've made a mistake etc.

Feel free to contact me with any questions or concerns!